Activities at Aerofin | February 2023

To give some insight into the daily activity of Aerofin Laboratories, this post will look at some of the cyclic corrosion testing taking place at Aerofin during the month of February 2023.

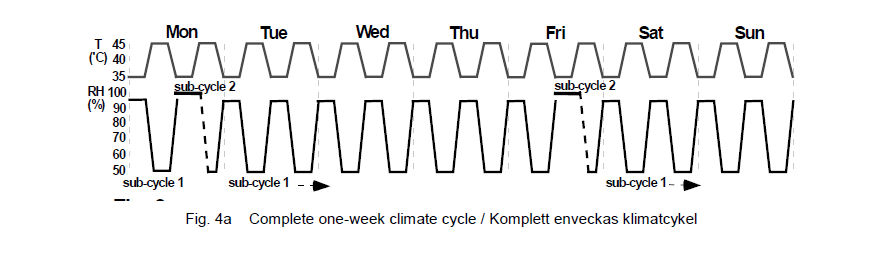

Recently finished: We are seeing more and more testing to automotive cyclic corrosion specifications such as “Accelerated corrosion tests” in accordance with the Volvo standard STD 423-0014. In short, the cycles come down to periods of high humidity, controlled humidity/temperature & corrosive salt exposure in a cyclic manner to rapidly replicate environment, where the generally accepted exposure duration is six weeks (six cycles).

This customer was interested in paint performance of external body parts where post exposure evaluations for degree of blistering, rusting, cracking, flaking and chalking were carried out in line with ISO 4628 and its subsequent sub standards.

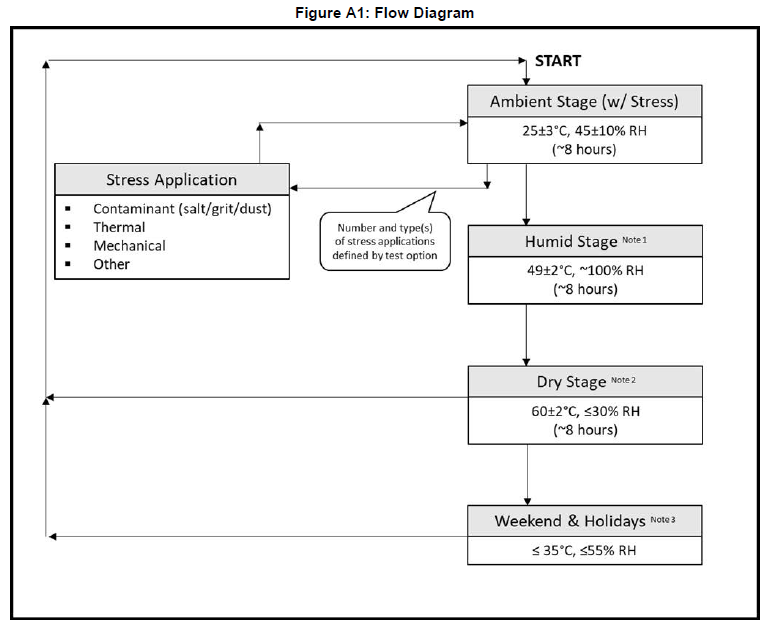

In progress: Currently under test and due to growing demand for testing to GMW 14872 we have dedicated equipment running this program and this program only. Automotive standard GMW 14872 cycles come down to periods of high humidity, controlled humidity/temperature & a period of “stress application”. These stress applications could be contaminant (salt/grit/dust), thermal or mechanical.

We are currently running the most commonly used stress application of a modified salt solution in a cyclic manner. The number of times test pieces / components are exposed to the salt solution is dictated by vehicle area. In this instance Underbody (UB) where the number of sprays is 4 per cycle. Post exposure evaluations include degree of rusting in accordance in accordance with ASTM D610.

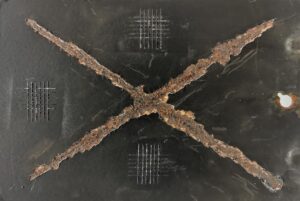

Test Piece with scribed marks to replicate damage.

The test pieces currently on test have had a scribe introduced prior to exposure. This replicates damage that may occur in service. The scribed lines are made through the coating to the substrate material where it is evaluated for flaking, blistering & scribe creep, post exposure in accordance with ASTM D1654.

This customer also requires a post exposure adhesion test. This test provides information on how the coating performs where no breach in the coating is made.

Planned: To commence we have some testing to VDA 621-415. The cyclic nature of this standard is relatively simple when compared to previously mentioned GMW 14872 and STD 423-0014. A week long cycle consisting of 1 day (24 hours), 4 days saturated atmosphere and 2 days (48 hours) room temperature. Although this standard has been withdrawn it is still worked to for its ease of use. The nature of the cycles coincides with (somewhat) normal working hours, meaning manual transfers from chamber could be implemented where this method wouldn’t be feasible with more complicated cycles.

Atmosfar Chamber at Aerofin Laboratories

We use Ascott analytical chambers for all of our cyclic corrosion testing with Aerofin Labs having capacity for basic cyclic tests such as the VDA 621-415 from 450 litres capacity.

For complex cycles such as FORD CETP00.00-L-467, ISO 16701, Scania STD 4319, Scania STD 4445, TPJLR.52.265, Volvo STD 1027-1375, Volvo STD 1027-14, Volvo STD 423-0014 and Volvo STD 4233, where functions such as oscillating spray (rain function) and minus temperatures are required, Aerofin has capacity up to 2600ltrs.

IF YOU’D LIKE TO KNOW MORE ABOUT THE WORK WE DO, OR TO WORK WITH US, PLEASE GET IN TOUCH.

CONTACT US.