Material Evaluation

Material Evaluation covers a broad range of testing including hardness testing, hydrogen embrittlement and metallurgical testing. Evaluating the physical properties of a material or coating. These types of tests can be performed at various stages of production to ensure quality material supply, process effectiveness and quality control.

Hydrogen Embrittlement

Testing defines the methods and acceptance criteria for coating and plating processes that can cause hydrogen embrittlement in steels.

Read More

Microhardness

Microhardness testing is used to assess a material or coatings suitability for function in service.

Read More

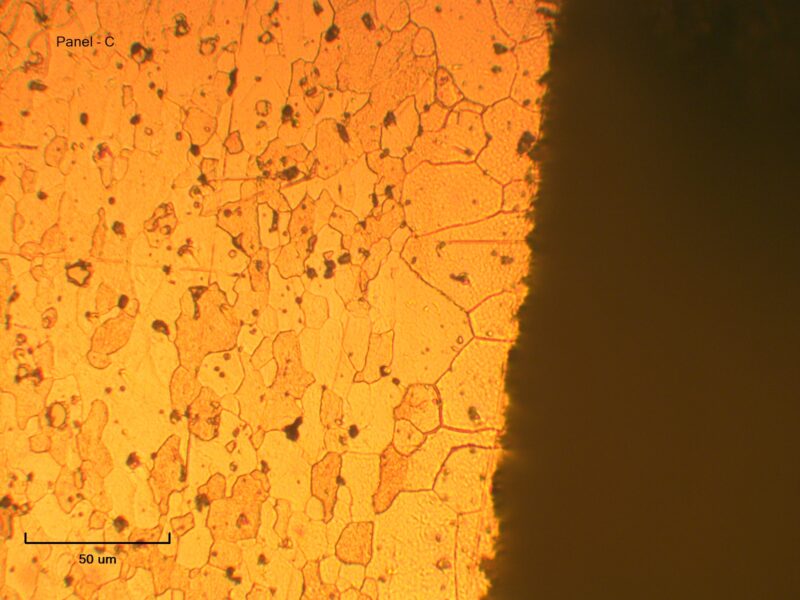

Chemical Processing Metallurgy

Metallographic examinations of metals to evaluate for unwanted properties introduced during chemical processing.

Read More

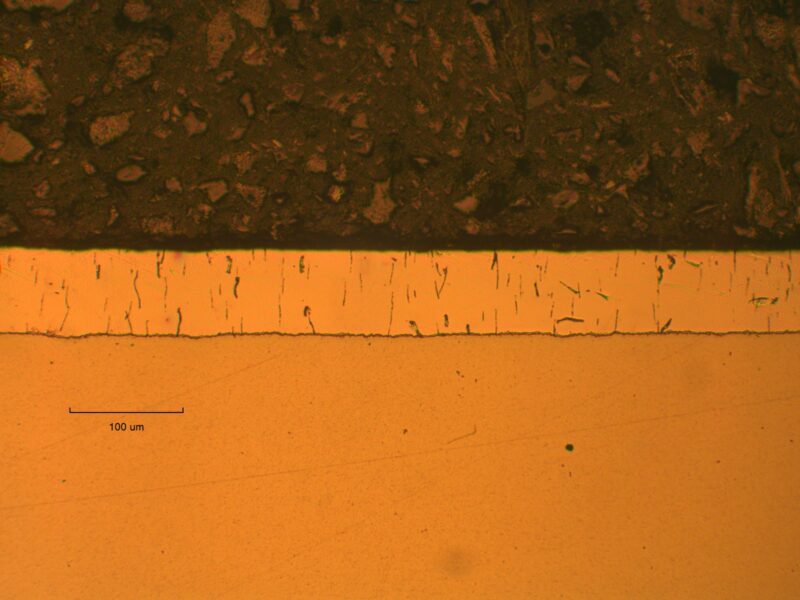

Heat Treat Metallurgy

Metallographic examinations of heat treated materials to reveal the constituents and structure of metals and their alloys.

Read More